Call Today: 916-259-1868

As industries strive for greater efficiency and precision, the role of linear motor manufacturers is becoming increasingly vital in the landscape of automation technology. According to a recent report by MarketsandMarkets, the global linear motor market is projected to reach $8.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 9.2%. This growth reflects the rising demand for high-performance motion control solutions across various sectors, including manufacturing, robotics, and transportation.

Experts in the field, such as Dr. Alan Price, a renowned figure in motion control systems, emphasize the transformative potential of these technologies. He stated, "Linear motors are revolutionizing the way manufacturers approach automation by offering both speed and accuracy that traditional systems cannot match." As we look ahead to 2025, it is essential to monitor key players in the linear motor industry who are driving innovation and pushing these advancements to new heights. Understanding their contributions will be critical for businesses seeking to leverage cutting-edge solutions in their operations.

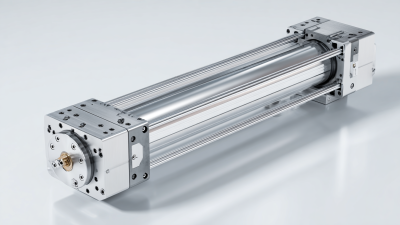

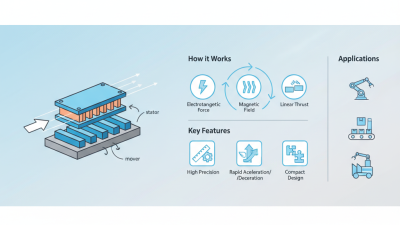

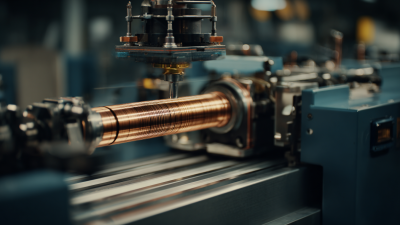

Linear motor technology is at the forefront of innovation, providing precise motion control and high-speed operation across various industries. Unlike traditional rotary motors, linear motors convert electrical energy directly into linear motion, resulting in faster response times and reduced maintenance. They are widely used in automation systems, robotics, and transportation applications, delivering enhanced efficiency and performance.

Tips: When considering the implementation of linear motors in your projects, it’s essential to evaluate the specific application requirements, including load characteristics and motion profiles. Understanding the differences in linear motor types—such as synchronous and asynchronous motors—can also help in selecting the right technology for optimal performance.

These motors find applications in cutting-edge technologies, such as electric vehicles and advanced manufacturing processes. Innovations in materials and designs continue to enhance the capabilities of linear motors, allowing for greater functionality and integration into complex systems. As industries push for higher productivity and precision, linear motors stand out as a key solution for achieving these goals.

Tips: Stay updated on the latest advancements in linear motor technology by following industry news and attending relevant trade shows. Collaborating with experts in motion control can also provide insights into the best practices for integrating these systems effectively.

Linear motors have emerged as game-changing components in various industries due to their unique features and advantages. Unlike traditional rotary motors, linear motors convert electrical energy directly into linear motion, resulting in higher efficiency and precision. This direct drive mechanism eliminates the need for mechanical components such as gears and belts, reducing wear and maintenance costs while enhancing reliability.

One of the significant benefits of linear motors is their capability for high-speed operation paired with exceptional acceleration, which is crucial in applications like robotics, manufacturing, and automated systems. Their inherent design allows for smooth motion with minimal vibration, contributing to better quality control and increased productivity. Additionally, linear motors can be easily integrated into existing systems, offering flexibility for various industrial needs, from assembly lines to automated guided vehicles. With the ongoing advancements in technology, the adoption of linear motors is set to rise, providing innovative solutions that cater to the evolving demands of modern industries.

| Manufacturer | Key Features | Benefits | Industry Applications |

|---|---|---|---|

| Manufacturer A | High-speed operation, compact design, low maintenance | Increased efficiency, reduced downtime, cost-effective | Automotive, Robotics, Packaging |

| Manufacturer B | Precision control, high force density, customizable | Enhanced performance, tailored solutions, reliability | Semiconductors, Aerospace, Medical devices |

| Manufacturer C | Integrated cooling, sensor feedback, modular design | Improved thermal management, accuracy, scalable | Electronics, Textile, Conveyor systems |

| Manufacturer D | Linear motion accuracy, robust construction, energy efficient | Longer service life, lower energy consumption, high reliability | Food processing, Assembly, 3D printing |

As the demand for precision and efficiency in various industries grows, linear motor manufacturers are stepping up their innovative approaches to meet the evolving needs of applications ranging from robotics to automation. According to a recent market research report, the global linear motor market is projected to grow at a CAGR of 8.5% between 2023 and 2030, emphasizing the critical role that innovative technology plays in maintaining competitiveness. Leading companies are investing in advanced materials and manufacturing techniques, aiming to enhance performance metrics while reducing costs.

One of the most noteworthy trends is the integration of artificial intelligence and machine learning in linear motor systems. This integration allows for real-time monitoring and predictive maintenance, significantly reducing downtime and increasing operational efficiency. For instance, a study indicated that AI-driven predictive maintenance can reduce maintenance costs by up to 30% and increase the lifespan of linear motors. Furthermore, the shift towards customization in manufacturing is prompting companies to develop modular linear motor designs, enabling users to tailor solutions specific to their operational requirements.

Additionally, sustainability has become a focal point for forward-thinking manufacturers. By adopting eco-friendly materials and energy-efficient designs, companies are not only addressing environmental concerns but also appealing to a market that increasingly prioritizes sustainability in industrial choices. As these manufacturers continue to innovate, the linear motor industry is set to transform, promising enhanced capabilities and efficiencies that will reshape multiple sectors in the years to come.

The linear motor market is poised for significant growth, driven by advancements in automation and precision engineering. As industries increasingly seek efficient solutions for motion control, several key players are emerging as leaders. These companies are known for their commitment to innovation and technological excellence, continually redefining performance standards in the linear motor sector.

Innovative solutions are essential for industries such as manufacturing, robotics, and transportation, where speed, accuracy, and reliability are paramount. The focus on sustainability and energy efficiency is also prompting manufacturers to develop eco-friendly linear motor technologies. Companies that prioritize R&D initiatives will play a critical role in shaping the future landscape of the linear motor market, catering to diverse applications while meeting stringent industry standards.

As we move towards 2025, monitoring these leading manufacturers will be crucial for anyone interested in the latest trends and developments in linear motor technology. Their ability to adapt to market demands, invest in cutting-edge research, and launch next-generation products will likely set the benchmark for the industry, making them integral to the advancement of automation solutions across various sectors.

The linear motor industry is expected to witness substantial advancements by 2025, driven by increasing demand for precision and efficiency across various sectors. According to a report by MarketsandMarkets, the linear motor market is projected to reach $7.3 billion by 2026, growing at a CAGR of 9.3% from 2021. This growth is largely fueled by the surge in automation and robotics applications, which necessitate high-speed linear motion solutions. Industries such as manufacturing, healthcare, and transportation are increasingly adopting linear motors to improve operational efficiency and reduce maintenance costs.

Future trends indicate a shift towards more compact and lightweight designs, which enhance the adaptability of linear motors in various applications. Advancements in materials and manufacturing techniques are enabling the development of more efficient linear motors with better performance metrics. Additionally, innovations in digital technologies, such as the integration of IoT and AI, are paving the way for smarter linear motor applications. These advancements not only promise improved energy efficiency but also facilitate predictive maintenance, reducing downtimes and operational disruptions. As the landscape evolves, stakeholders in the linear motor supply chain must stay informed about these emerging trends to remain competitive and leverage new opportunities in the market.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.