Call Today: 916-259-1868

In the rapidly evolving field of motion control, linear direct drive systems are positioning themselves at the forefront of innovation. As we look towards 2025, the demand for precision, speed, and efficiency in automation drives the development of advanced linear direct drive technologies. These systems, which utilize direct motor-driven mechanisms to achieve accurate and fast linear movements, are revolutionizing sectors ranging from manufacturing to robotics. This article explores the top 10 linear direct drive systems that are set to make a significant impact on the industry, highlighting their unique features and anticipated applications.

The integration of linear direct drive technology is not only enhancing operational performance but also redefining the benchmarks for productivity and reliability. As we delve into the capabilities of these advanced systems, we will provide key insights and tips for industry professionals looking to leverage the latest developments in linear direct drive. By understanding the advantages and functionalities of these innovative solutions, organizations can better navigate the future of motion control and elevate their operational efficacy.

Join us as we explore how these transformative systems are shaping the landscape and what the future holds for linear direct drive technology.

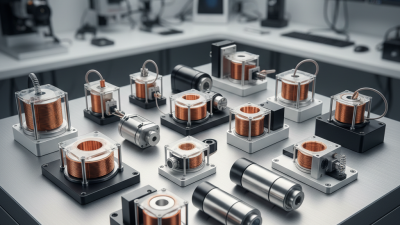

As we approach 2025, the landscape of motion control is undergoing a significant transformation, thanks to revolutionary innovations in linear direct drive technology. These systems offer unmatched precision, speed, and reliability, making them ideal for a variety of applications, from industrial automation to robotics and medical devices. The key to their success lies in the elimination of traditional mechanical components, such as gears and belts, which often introduce backlash and wear. Instead, direct drive systems utilize high-performance motors directly connected to the load, ensuring a more efficient and accurate movement.

Tips: When choosing a linear direct drive system, consider factors such as load requirements, speed, and the necessary precision for your application. It's essential to evaluate compatibility with existing systems and software for seamless integration.

The advancements in materials and control algorithms have also contributed to the rise of linear direct drives. Smart sensors and AI-driven control systems enhance performance by providing real-time feedback and adaptive learning capabilities. These features not only improve operational efficiencies but also reduce downtime, ultimately leading to cost savings.

Tips: Investing in training for your team can maximize the potential of your new linear direct drive system. Understanding the intricacies of the technology can lead to improved performance and innovative applications that push the boundaries of what’s possible.

Linear direct drive systems are transforming the landscape of motion control by offering significant advantages over traditional motors. Unlike conventional rotary motors, linear direct drives deliver motion in a straight line, eliminating the need for complex mechanical transmissions such as belts or gears. This direct coupling of force leads to increased efficiency and precision, making them ideal for high-performance applications in various industries, from manufacturing to robotics.

One of the primary benefits of linear direct drive systems is their high level of accuracy. They can achieve remarkable positioning resolution, which is essential for tasks that require meticulous movement, such as semiconductor fabrication or medical device assembly. Additionally, these systems experience less wear and tear because they have fewer moving parts, resulting in lower maintenance costs and longer operational lifespans.

Tip: When considering the integration of linear direct drive systems into your operations, evaluate your specific application requirements thoroughly. Assess factors like load capacity and speed to ensure you select the most appropriate system that maximizes efficiency and performance.

Furthermore, linear direct drives are known for their rapid acceleration and deceleration capabilities, which enhances productivity. As industries increasingly demand faster and more responsive machines, the adoption of these innovative systems will likely continue to rise, enabling businesses to stay competitive in the fast-paced global market.

Tip: Always consult with a specialist before upgrading your equipment with linear direct drives—this can help tailor a solution that meets your exact needs and optimizes your workflow.

Linear direct drive systems are transforming motion control across a variety of industries, enabling unmatched precision and efficiency. In the manufacturing sector, these systems are crucial for automation processes, allowing for precise positioning and rapid movement without the mechanical backlash associated with traditional systems. This capability is invaluable in applications such as robotics, where accuracy in repetitive tasks directly correlates to product quality and operational efficiency.

In addition to manufacturing, the automotive and aerospace industries are benefiting significantly from linear direct drive technology. These systems allow for more responsive control in assembly lines and testing environments, leading to faster production cycles and reduced downtime.

Moreover, in the medical field, linear direct drives are essential for sophisticated equipment such as MRI machines and surgical robots, where they ensure smooth, accurate movements that are vital for patient safety and outcome accuracy. As industries continue to adopt these systems, the potential for innovation and enhanced performance seems boundless.

The future of motion control technology is poised for significant advancements, particularly with the emergence of linear direct drive systems. These systems are becoming increasingly vital across various sectors, including robotics, healthcare, and manufacturing. By providing precise control of motion without the need for complex mechanical systems, linear direct drive systems can enhance efficiency, reduce wear, and improve the overall performance of machinery. As the world gravitates toward automation, the demand for such direct drive systems is expected to escalate, driving further research and innovation in this field.

Emerging trends in motion control technology also highlight the integration of artificial intelligence and collaborative robotics. As outlined in recent patent analyses, advancements in collaborative robot technology are paving the way for more adaptable and intelligent systems that can work alongside humans in diverse environments. This synergy between humans and robots not only optimizes production but also reduces operational risks. Additionally, the incorporation of advanced sensor technologies will enable these systems to respond in real-time to dynamic changes in their environment, positioning them as key players in the future landscapes of various industries.

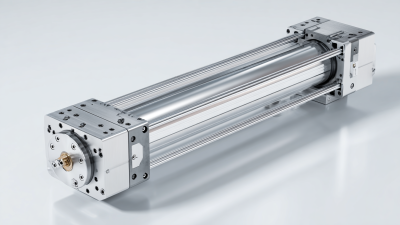

The year 2025 marks a pivotal moment in the evolution of motion control technology, particularly with linear direct drive systems. These systems, known for their precision and efficiency, have undergone significant advancements, resulting in a host of innovative solutions that stand out in the marketplace. A comparative analysis of the top 10 linear direct drive systems reveals crucial metrics such as speed, torque, and overall energy efficiency, which play a vital role in selecting the right system for specific applications.

Among these leading systems, features such as enhanced thermal management, simplified installation processes, and compatibility with advanced control algorithms set them apart. Companies are increasingly leveraging these capabilities to improve automation in industries ranging from robotics to semiconductor manufacturing. By focusing on key performance indicators and user-friendly designs, these cutting-edge systems not only promise improved operational performance but also pave the way for more sustainable practices within the field of motion control.

| System Type | Max Force (N) | Max Speed (m/s) | Precision (mm) | Weight (kg) | Power Consumption (W) |

|---|---|---|---|---|---|

| Linear Motor A | 500 | 2.5 | 0.01 | 15 | 200 |

| Linear Motor B | 600 | 3.0 | 0.02 | 18 | 220 |

| Linear Motor C | 700 | 3.5 | 0.015 | 20 | 240 |

| Linear Motor D | 450 | 2.0 | 0.025 | 12 | 180 |

| Linear Motor E | 550 | 2.8 | 0.018 | 17 | 210 |

| Linear Motor F | 800 | 4.0 | 0.012 | 25 | 270 |

| Linear Motor G | 650 | 3.2 | 0.014 | 19 | 230 |

| Linear Motor H | 720 | 3.8 | 0.013 | 22 | 260 |

| Linear Motor I | 490 | 2.1 | 0.019 | 14 | 195 |

| Linear Motor J | 530 | 2.7 | 0.017 | 16 | 205 |

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.