Call Today: 916-259-1868

The advent of linear motion control systems is set to revolutionize industrial automation, significantly enhancing operational efficiency across various sectors. According to a recent report by the International Federation of Robotics, the global market for automation technology is expected to reach $214 billion by 2025, driven by advances in linear motion solutions that improve precision and speed. These systems play a crucial role in minimizing downtime and increasing productivity, as evidenced by a McKinsey study indicating that companies adopting advanced automation technologies can boost their overall productivity by up to 30%. As industries strive for higher output and responsiveness in a competitive market, the integration of linear motion control systems emerges as a key strategy, propelling businesses towards modernization and sustainability.

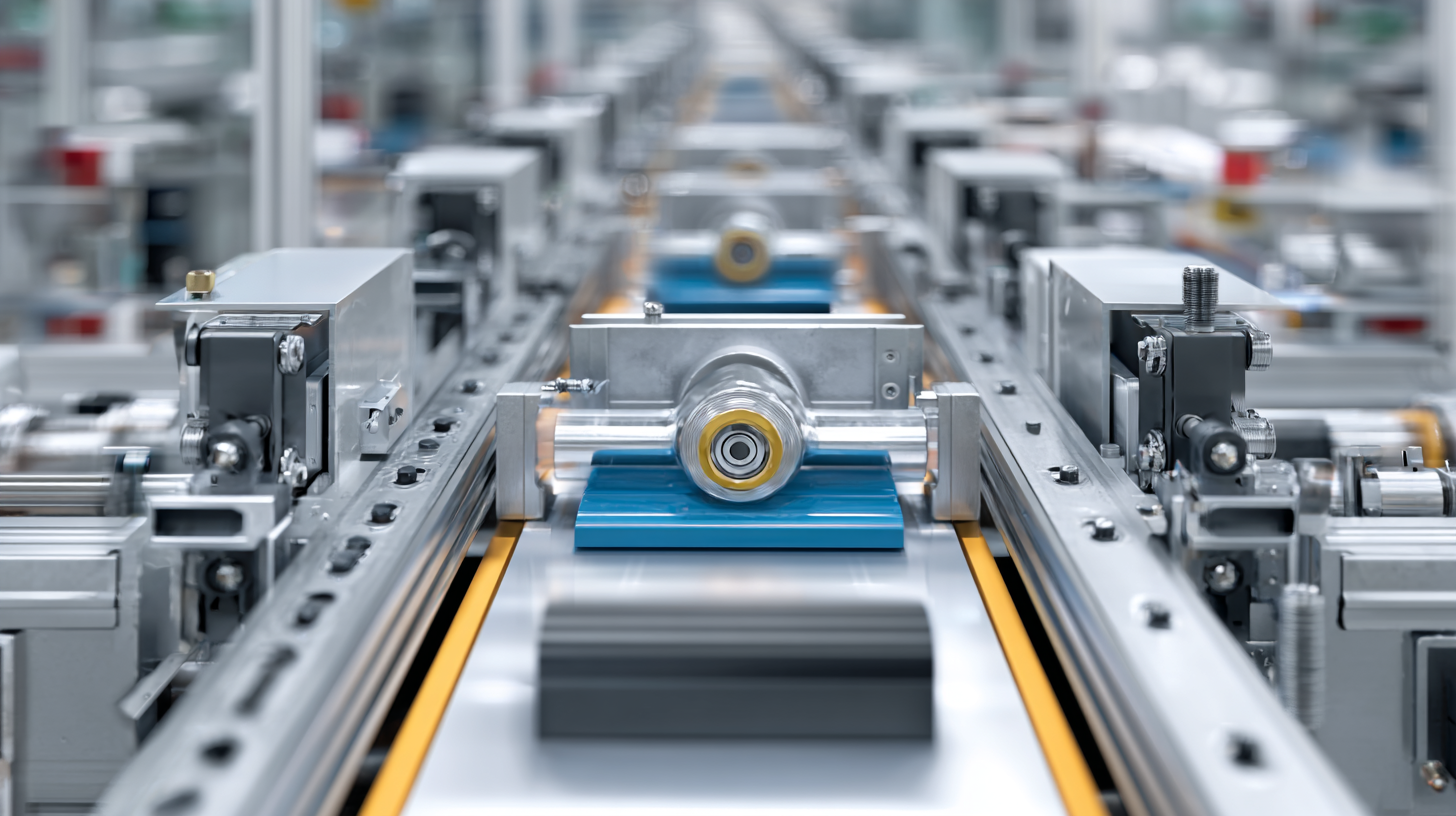

The evolution of linear motion control systems has significantly transformed the landscape of industrial automation. From early mechanical systems to today's advanced programmable and automated solutions, these technologies have paved the way for increased precision and efficiency in manufacturing processes. The integration of linear motion control in robotics, conveyor systems, and CNC machines enables smoother operations and reduces the margin for error, thereby enhancing overall productivity.

Tip: When implementing linear motion control systems, consider the application’s specific requirements—such as load capacity and speed—to select the right components that will optimize performance and longevity.

Moreover, technological advancements, such as the integration of sensor technology and artificial intelligence, have revolutionized linear motion systems. These innovations not only facilitate real-time monitoring and adjustments but also enable predictive maintenance, minimizing downtime. As industries continue to embrace automation, understanding the evolution of these systems will help organizations leverage their full potential.

Tip: Regular training for staff on the latest linear motion technologies can lead to improved utilization and support ongoing innovation in operational processes.

Linear motion control systems are transforming industrial operations by enhancing precision and efficiency in various applications. One of the key benefits of implementing these solutions is improved accuracy in positioning and movement. By utilizing advanced feedback mechanisms, linear motion control systems can achieve high levels of repeatability, which is crucial in sectors such as manufacturing and robotics. This not only minimizes errors but also significantly reduces material waste and operational costs.

Additionally, linear motion control systems allow for faster cycle times, enabling industries to boost their overall productivity. The ability to execute rapid movements and precise control contributes to shorter lead times and increased throughput. Furthermore, these systems can be integrated with automation technologies, such as robotic arms and CNC machines, creating a seamless workflow that enhances efficiency across the production line. This integration not only streamlines operations but also fosters innovation by enabling the development of more complex and sophisticated automation solutions.

Linear motion control systems are increasingly transforming various industries by enhancing operational efficiency and productivity. Their real-world applications span diverse fields such as robotics, construction, and transportation. For instance, the integration of linear actuators in robotic systems enables precise movement control, significantly improving task execution in complex scenarios. This technology allows for real-time adjustments and optimizations, exemplified by advancements in robotic hand control systems that leverage EEG signals for intricate finger movements.

**Tips:** To maximize the efficiency of linear motion systems, consider the use of hybrid control frameworks that combine traditional and intelligent algorithms. These frameworks can adapt to real-time data, thereby streamlining workflows and reducing operational waste. Additionally, incorporating feedback mechanisms can enhance system responsiveness, making them suitable for dynamic environments.

In construction, linear motion systems play a crucial role in optimizing repetitive tasks, such as the execution of time-cost trade-offs in project management. By utilizing metaheuristic-based frameworks, project managers can achieve better resource allocation and schedule adherence, ultimately driving down costs while maintaining high productivity levels. Emphasizing the importance of these systems highlights their potential to revolutionize industry practices and drive sustainable growth.

The adoption of automation technologies is not without its challenges and considerations. While Industry 4.0 promises significant boosts in efficiency by integrating connected devices and computer analytics, manufacturers must navigate several hurdles to fully benefit from these advancements. Key challenges include the high initial investment costs, the need for skilled workforce training, and the integration of legacy systems into modern automated frameworks. As businesses strive to innovate, they must also remain vigilant about cybersecurity risks, which can become more pronounced with interconnected systems.

Tips: When implementing automation, consider a phased approach that allows for gradual integration of new technologies while monitoring their impact on operations. It's essential to invest in training programs that will upskill current employees, equipping them to work alongside advanced machinery. Furthermore, prioritize cybersecurity measures from the outset to protect sensitive data and maintain operational integrity.

In addition, businesses should thoroughly evaluate the specific needs of their operations before adopting new technologies. Understanding the unique challenges faced in different sectors can aid in making informed decisions about which automation solutions will deliver the greatest return on investment. Engaging with industry experts during the planning phase can provide valuable insights and strategies for successful implementation.

The future of linear motion control systems in industry looks promising, driven by rapid advancements in technology and the increasing demand for efficiency and precision. One of the key trends is the integration of artificial intelligence and machine learning into motion control systems. This integration allows for real-time data analysis and adaptive control, enabling systems to optimize their performance based on current operational conditions, thereby reducing downtime and enhancing productivity.

Another significant trend is the development of more compact and lightweight linear motion solutions that utilize advanced materials and smart design. These innovations not only save space in manufacturing environments but also improve energy efficiency, contributing to a more sustainable production process. Additionally, the rise of Industry 4.0 is pushing for greater connectivity, where linear motion systems communicate seamlessly with other machinery and the cloud, providing endless possibilities for system monitoring, predictive maintenance, and automation scalability, ultimately leading to a more intelligent and efficient industrial landscape.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.