Call Today: 916-259-1868

The future of linear motors is poised for remarkable advancements, driven by innovations from leading linear motor manufacturers. According to a report by MarketsandMarkets, the global linear motor market is expected to reach USD 3.7 billion by 2025, growing at a CAGR of 10.2% from 2020. This growth is largely attributed to the increasing demand for precise motion control across various industries, including automation, aerospace, and medical devices.

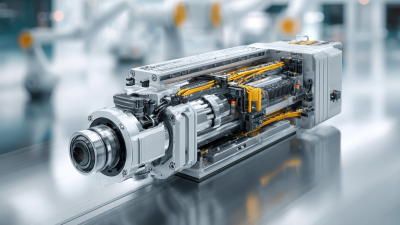

Renowned manufacturers are investing heavily in R&D to develop high-performance, cost-effective linear motor solutions that meet the evolving needs of automation and smart manufacturing. With significant advancements in materials science and design engineering, these manufacturers are pushing the boundaries of speed, efficiency, and reliability. As we delve into the innovations from these industry leaders, we will explore how their cutting-edge technologies are reshaping the landscape of linear motion and setting new standards for the future.

Linear motor technology has been gaining traction across various industries due to its efficiency and precision. Unlike traditional rotary motors, linear motors deliver linear motion directly, which significantly reduces mechanical complexity. According to a report by ResearchAndMarkets, the global linear motor market is expected to grow at a CAGR of 7.2% from 2021 to 2026, reaching a valuation of approximately $5 billion by the end of the forecast period. This growth reflects the increasing demand for automation and the need for high-speed, accurate positioning systems in applications like robotics, transportation, and manufacturing.

Linear motor technology has been gaining traction across various industries due to its efficiency and precision. Unlike traditional rotary motors, linear motors deliver linear motion directly, which significantly reduces mechanical complexity. According to a report by ResearchAndMarkets, the global linear motor market is expected to grow at a CAGR of 7.2% from 2021 to 2026, reaching a valuation of approximately $5 billion by the end of the forecast period. This growth reflects the increasing demand for automation and the need for high-speed, accurate positioning systems in applications like robotics, transportation, and manufacturing.

Tips for optimizing linear motor performance include ensuring proper alignment and calibration during installation. Misalignment can lead to increased wear and reduced efficiency, which may shorten the motor's lifespan. Additionally, it’s essential to consider the thermal management of the system, as overheating can severely impact the motor's operation and lead to premature failure.

As advancements continue, leading manufacturers are innovating in design and materials, enhancing the performance and application range of linear motors. For instance, the integration of advanced control algorithms can allow for smoother operation and greater energy efficiency, catering to market demands for sustainable practices.

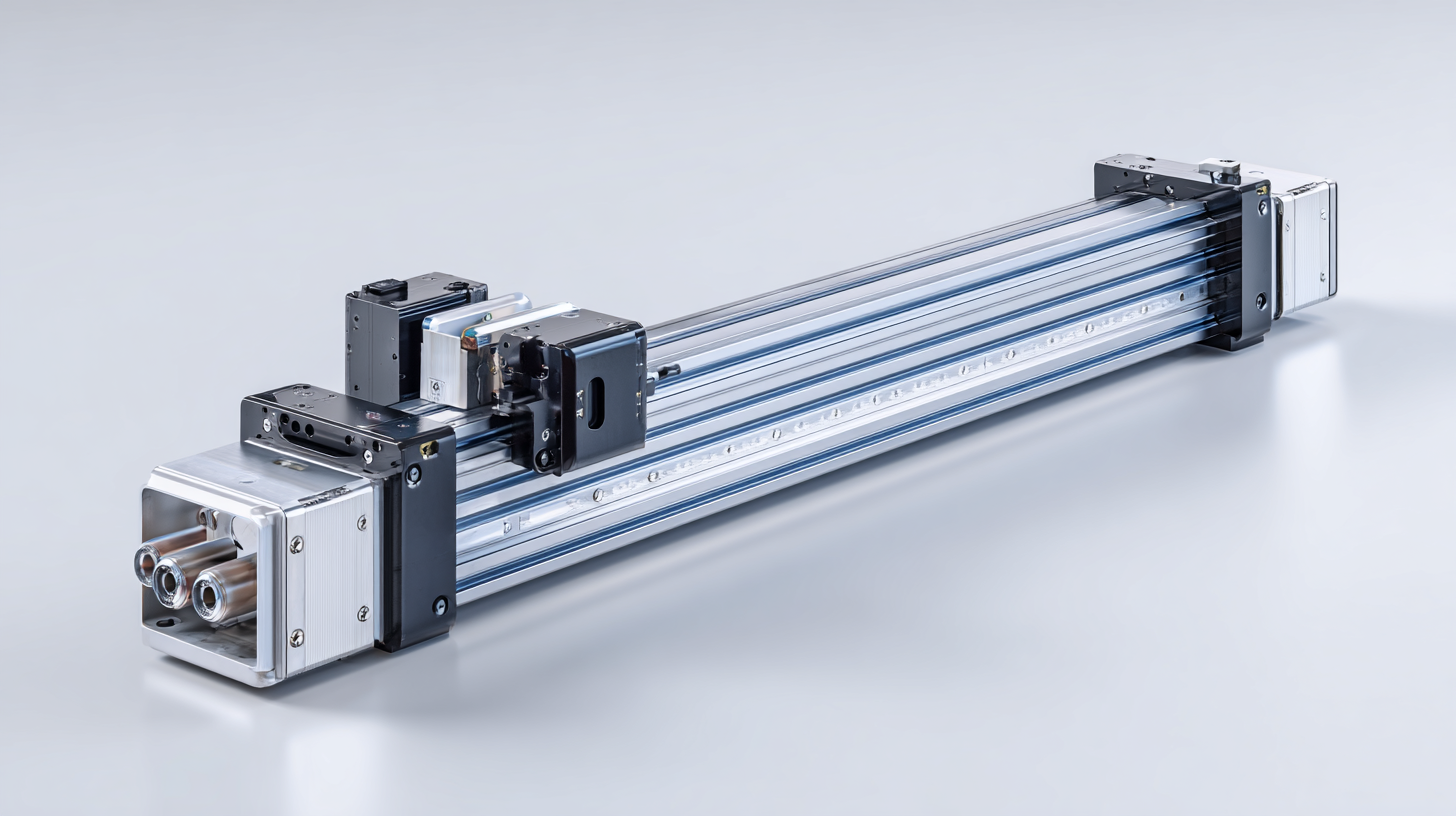

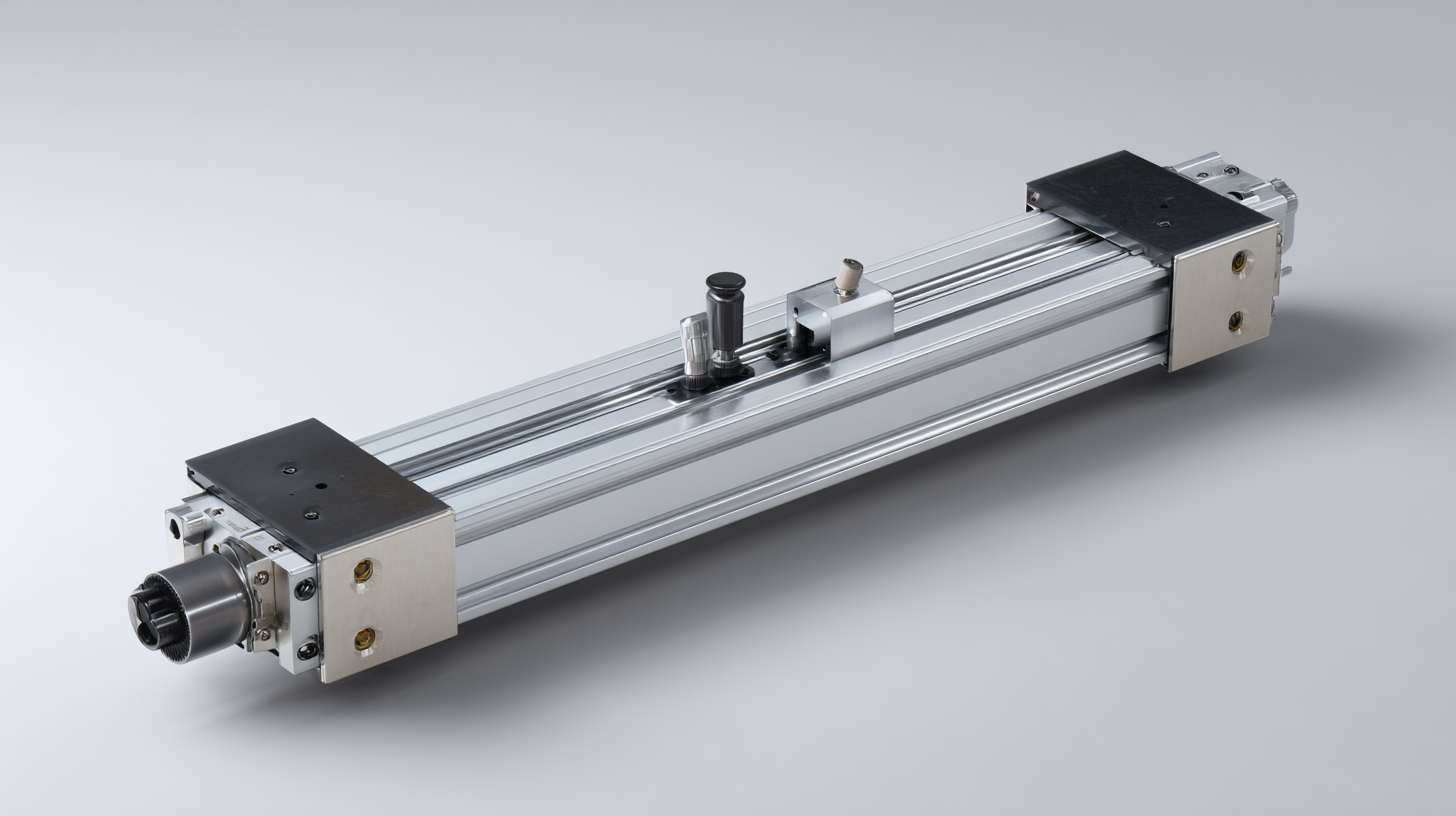

The future of linear motors is being shaped by several innovative advancements from leading manufacturers, focusing on efficiency, performance, and application versatility. One key innovation is the development of high-frequency linear motors, which significantly enhance speed and precision in various applications, including robotics and automation. These motors utilize advanced materials and improved designs, allowing for smoother operation and reduced wear over time, thus extending their lifespan and reliability in demanding environments.

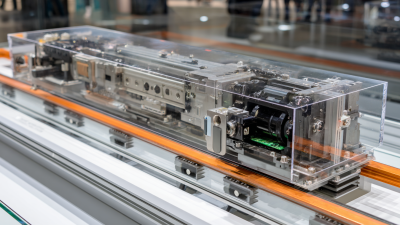

Another significant trend is the integration of smart technologies into linear motor systems. By incorporating IoT (Internet of Things) capabilities, manufacturers are creating motors that can communicate with other devices and systems, enabling real-time monitoring and predictive maintenance. This innovation not only optimizes system performance but also minimizes downtime and maintenance costs, making linear motors more attractive for industries ranging from manufacturing to transportation. As these key innovations continue to evolve, they are set to redefine the landscape of linear motor applications across multiple sectors.

The competitive landscape of linear motor manufacturers is evolving rapidly, driven by technological advancements and growing applications across various industries. A recent market analysis from MarketsandMarkets forecasts that the linear motor market will grow from $3.5 billion in 2021 to $5.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.3%. This growth is largely fueled by the increasing demand for precision motion control in sectors such as robotics, automation, and electric vehicles.

Leading manufacturers like Siemens, THK, and Fanuc are at the forefront of this innovation wave. Siemens, for instance, has introduced linear motors that feature advanced cooling technologies, enhancing efficiency by up to 15%. On the other hand, Fanuc's latest models emphasize energy savings, as highlighted in their 2022 sustainability report, which showed a reduction in operational energy consumption by 25% compared to previous generations. Meanwhile, THK's proprietary linear motor design allows for higher acceleration and deceleration rates, catering to the growing needs for rapid manufacturing processes.

The comparative analysis of these manufacturers reveals a decisive trend towards sustainability and efficiency, with consistent investment in R&D. According to a study by ResearchAndMarkets, the focus on integrative solutions—combining linear motors with AI and IoT technologies—is paving the way for smarter industrial applications. This strategic direction suggests that the future of linear motors will not only hinge on performance but also on how well these companies can adapt to the ever-changing technological landscape.

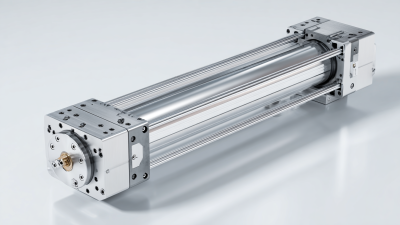

The linear motors market is witnessing rapid advancement, driven by innovative technologies and increasing applications across various industries. Recent product launches highlight the focus on high-performance linear motor stages, featuring enhanced dynamics and precision guiding systems. These developments not only improve efficiency but also broaden the scope of possible applications, making linear motors an appealing choice for automation and precision motion control.

Moreover, the growing demand for high torque stepper motors and precision torque motors emphasizes their critical role in sectors that require high acceleration and torque density. As the global linear motors market is projected to reach over $2.5 billion by 2031, the trend indicates a shift towards more sophisticated motor technologies, such as slotted and slotless motors, catering to specific industrial needs.

The advancements in linear motor technology not only promise enhanced functionality but also push the boundaries of what’s possible in automation and motion solutions.

The development and deployment of linear motors face several significant challenges that need to be addressed for their widespread adoption. High manufacturing costs remain a primary obstacle, with reports indicating that the production of linear motors can exceed conventional motors by up to 30%, which has deterred many manufacturers from integrating them into their operations. Additionally, the precision required for linear motors, particularly in applications such as semiconductor manufacturing and automated transportation, places stringent demands on material quality and design specifications.

Another critical challenge lies in the energy efficiency and heat management of linear motors. A recent study from the International Electrotechnical Commission highlighted that while linear motors can achieve efficiency rates of over 90%, improper thermal management can lead to performance degradation. Leading manufacturers are investing in innovative materials and cooling solutions to mitigate this issue, including the use of advanced composites and efficient heat dissipation technologies. These solutions not only improve operational efficiency but also extend the lifespan of linear motors, making them more attractive for industries aiming for long-term sustainability.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.