Call Today: 916-259-1868

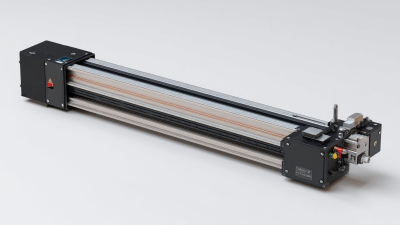

A flat linear motor is an innovative and versatile technology that has gained significant attention in industrial applications and automation systems. Unlike traditional rotary motors, flat linear motors provide direct linear motion with high precision and efficiency, making them ideal for various applications, from robotics to conveyor systems. This type of motor operates on the principles of electromagnetic force, which enables it to achieve rapid acceleration and deceleration, facilitating seamless movement along a predetermined path.

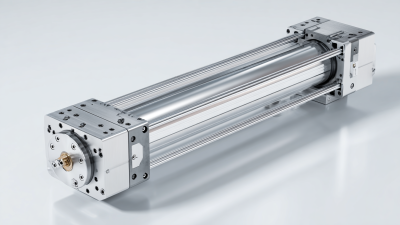

The design of a flat linear motor typically consists of a stationary part, known as the stator, and a moving part, known as the mover. The stator generates a magnetic field when electric current passes through it, while the mover contains coils that interact with this magnetic field to produce linear thrust. This unique configuration allows for a compact and lightweight solution that can be easily integrated into existing systems. As industries continue to seek ways to enhance productivity and efficiency, understanding how flat linear motors work and their advantages will become increasingly important for engineers and designers alike.

In summary, the flat linear motor represents a significant advancement in motion control technology, offering a range of benefits that traditional motors cannot match. By exploring its operational principles and applications, we can gain valuable insights into the future of automation and the role these motors will play in shaping modern engineering solutions.

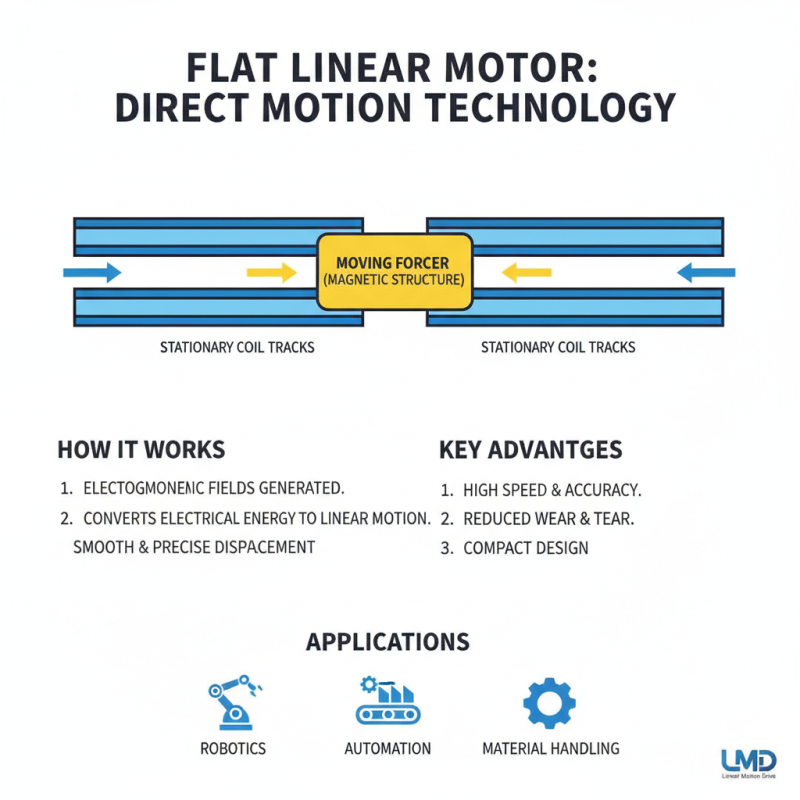

A Flat Linear Motor is defined as an electromechanical device that converts electrical energy directly into linear motion. This type of motor operates through electromagnetic fields generated between fixed coils and a moving solid magnet or magnetic structure. Unlike traditional rotational motors, Flat Linear Motors are designed to provide a smooth and precise linear displacement, making them ideal for applications requiring high-speed and accurate movements. They are extensively used in industries such as robotics, automation, and material handling.

Key characteristics of Flat Linear Motors include high efficiency, compact design, and ease of integration into existing systems. According to industry reports, the efficiency of Flat Linear Motors can exceed 90%, significantly reducing energy consumption compared to conventional systems. Their low profile enables them to fit into tight spaces, and their modular design allows for straightforward installation and maintenance. Additionally, these motors have a high thrust-to-weight ratio, contributing to better performance in applications demanding rapid acceleration.

**Tips:** When considering the integration of Flat Linear Motors into your system, evaluate the required travel distance and load capacity to ensure optimal performance. Additionally, conducting a thorough analysis of the operating environment can help to mitigate any potential performance issues related to thermal management or environmental factors, which are crucial for maintaining efficiency and longevity.

Flat linear motors are streamlined electromechanical devices designed to produce linear motion without the need for mechanical components such as gears or linkages. The principle of operation behind these motors relies on electromagnetic principles, where coils generate magnetic fields that interact with permanent magnets or other magnetic components. When electric current passes through the coils, it creates a magnetic field that induces motion, enabling the system to achieve precise positioning and rapid acceleration.

The configuration of flat linear motors allows for an efficient design, as the stator and rotor components are often laid out in a flat planar format. This arrangement not only minimizes space consumption but also enhances thermal management, allowing for better performance under varying load conditions. The synchronous nature of the motor's operation ensures that motion can be controlled with high accuracy, making it suitable for various applications including automation, robotics, and materials handling. By varying the current and frequency supplied to the coils, users can fine-tune the motor's speed and force, resulting in a versatile and responsive motion system.

This chart illustrates the efficiency and thrust output of flat linear motors at varying power inputs. The data reflects a typical performance profile and serves to demonstrate how these motors generate motion.

Flat linear motors are increasingly adopted across various industries due to their unique design and efficient operation. These motors utilize electromagnetic forces to provide direct linear motion without the need for traditional rotary components, such as gears or belts. This capability makes them ideal for applications requiring precise positioning and high-speed linear movement.

In manufacturing, flat linear motors are commonly used in automation systems, where they enhance the performance of robotic arms and conveyor systems. Their ability to deliver quick and accurate movements significantly boosts productivity and reduces downtime. In the semiconductor industry, they play a critical role in wafer handling and processing equipment, ensuring that components are moved with the utmost precision. Additionally, in medical technology, flat linear motors are utilized in devices such as diagnostic equipment and surgical robots, where reliability and accuracy are paramount.

Tip: When considering the integration of flat linear motors into your operations, evaluate factors such as load capacity, space constraints, and the required speed of movement. Ensuring that these parameters align with your applications will help optimize performance and efficiency.

Moreover, the versatility of flat linear motors extends to the automotive sector, where they are employed in electric vehicle charging systems and precision assembly lines. Their compact design allows for easier integration into existing systems, making them an ideal choice for manufacturers looking to upgrade their technologies without extensive modifications.

Tip: Always consult with experts to assess the specific needs of your industry, as tailored solutions can significantly enhance the advantages offered by flat linear motors.

| Industry | Application | Advantages |

|---|---|---|

| Manufacturing | Automated Assembly Lines | High precision, speed, and flexibility in movement. |

| Transportation | Maglev Trains | Reduced friction, high-speed travel, and low maintenance. |

| Electronics | Pick and Place Robots | Enhanced accuracy in component placement and reduced cycle time. |

| Aerospace | Wing Flap Actuators | High reliability and performance under extreme conditions. |

| Medical | Precision Surgical Robots | Improved surgical outcomes with minimal invasion. |

Flat linear motors have emerged as a transformative technology in various applications due to their unique design and operational principles. One significant advantage of flat linear motors over traditional motors is their ability to provide direct linear motion without the need for mechanical conversion. This results in higher efficiency and reduced maintenance, as there are fewer moving parts subject to wear and tear. Additionally, the compact design of flat linear motors allows for more flexible installation options, enabling them to fit in spaces where traditional motors might be cumbersome.

Another advantage is their enhanced performance characteristics. Flat linear motors deliver precise control over motion, which is crucial for applications requiring high accuracy. The absence of cogging effects, typical in traditional motors, further facilitates smooth and consistent movement. This can be particularly beneficial in robotics and automation, where precision is paramount. Moreover, they often exhibit faster acceleration and deceleration rates, leading to improved responsiveness in dynamic systems.

Tips: When considering the switch to flat linear motors, it is essential to assess the specific requirements of your application. Ensure that the motor’s specifications align with your performance needs, as well as with the spatial constraints of your installation site. Additionally, proper integration with control systems can maximize the benefits of flat linear technology, offering a streamlined solution to improve overall operational efficiency.

As the demand for precision and efficiency continues to grow in various industries, flat linear motors are evolving to meet the challenges of modern engineering. These motors are capable of providing direct linear motion with high acceleration and reduced mechanical wear compared to traditional rotary systems. Future developments in flat linear motor technology are likely to focus on enhancing performance characteristics, such as increasing speed and torque while minimizing energy consumption. Innovations in materials and manufacturing processes will play a crucial role in achieving these advancements.

Another significant trend is the integration of smart technologies into flat linear motors. The incorporation of sensors and advanced control algorithms can facilitate real-time monitoring and predictive maintenance, resulting in increased operational efficiency and reduced downtime. Additionally, there is an increasing interest in the application of these motors in emerging fields like robotics, automation, and electric vehicles, where compact design and high performance are essential. As research continues and new applications are discovered, flat linear motors are poised to take on a pivotal role in shaping the future of motion technology.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.