Call Today: 916-259-1868

In the continuously evolving landscape of industrial automation, the magnetic linear drive stands out as a pivotal technology poised to enhance efficiency significantly. As organizations strive to optimize energy consumption amidst rising operational costs, research indicates that integrating magnetic linear drives can yield energy savings of up to 30%, according to a recent report by the International Energy Agency (IEA). These drives not only reduce energy usage but also minimize maintenance needs due to their lack of physical contact between moving parts, further lowering operational costs.

With an increasing demand for automation solutions that are both economical and efficient, industries are progressively adopting magnetic linear drives, which are projected to account for a substantial portion of the market by 2025, as outlined in a report by MarketsandMarkets. This innovation represents a transformative step towards sustainable manufacturing practices, making it imperative for businesses to explore and implement this technology to stay competitive in the marketplace.

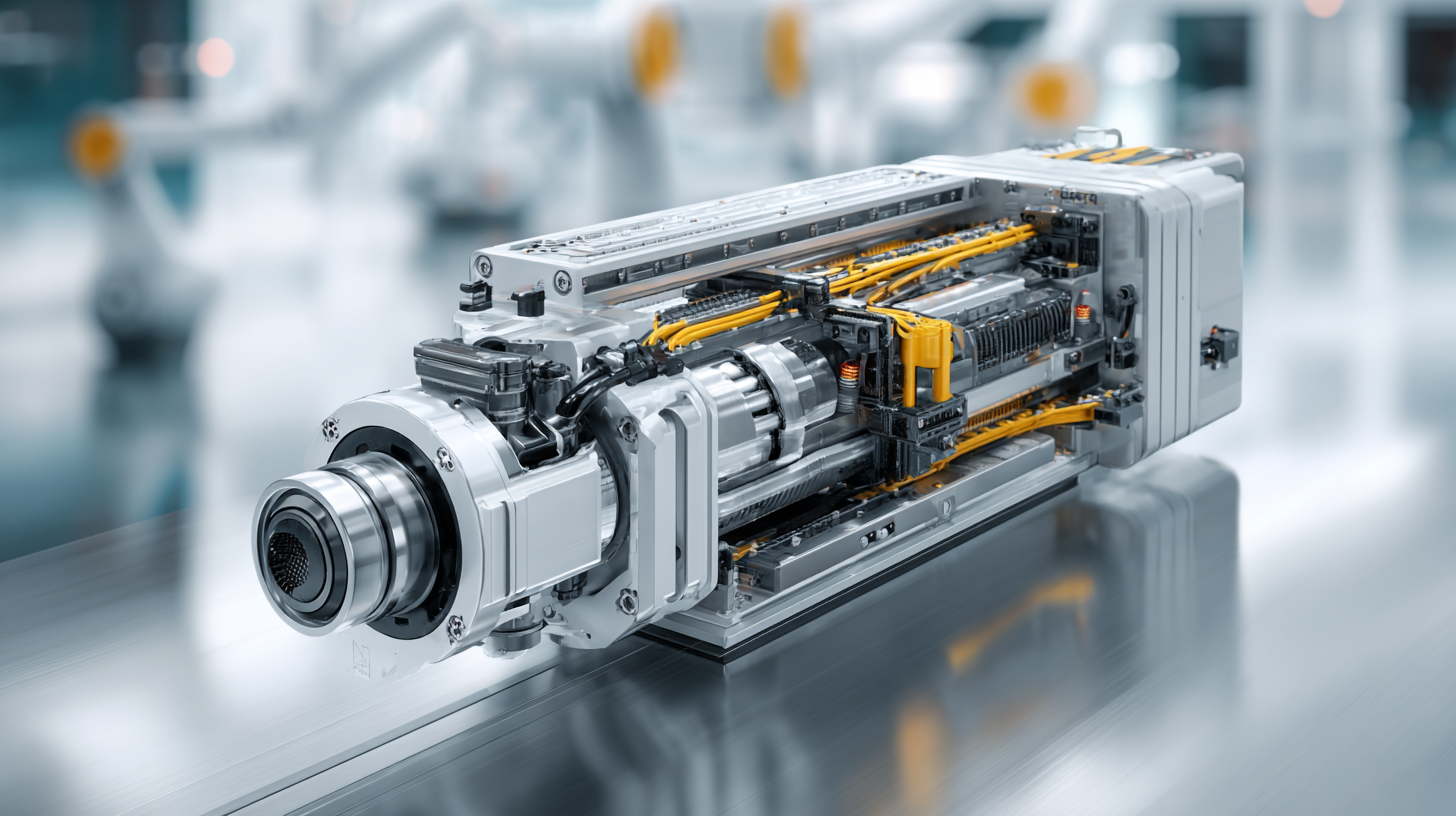

Magnetic linear drives (MLDs) represent a substantial advancement in automation technology, primarily through their unique mechanism of action that utilizes electromagnetic forces to propel an object in a straight line. Unlike traditional linear actuators that rely on rotary motion converted to linear movement, MLDs directly convert electrical energy into linear motion. This system eliminates mechanical friction and engages only the necessary magnetic fields to generate movement, resulting in significantly improved efficiency.

Magnetic linear drives (MLDs) represent a substantial advancement in automation technology, primarily through their unique mechanism of action that utilizes electromagnetic forces to propel an object in a straight line. Unlike traditional linear actuators that rely on rotary motion converted to linear movement, MLDs directly convert electrical energy into linear motion. This system eliminates mechanical friction and engages only the necessary magnetic fields to generate movement, resulting in significantly improved efficiency.

According to a report by MarketsandMarkets, the shift towards magnetic drive systems could lead to energy savings of up to 30%. This efficiency can be attributed to reduced wear and tear on components, allowing for longer operational lifespans and lower maintenance costs. Additionally, MLDs can achieve high-speed operations and precise positioning, making them ideal for high-demand industries, including automotive and manufacturing. As companies increasingly adopt Industry 4.0 technologies, the integration of MLDs is not only enhancing operational output but is also critical in meeting sustainability goals.

Magnetic linear drives are at the forefront of revolutionizing automation, offering significant energy efficiency benefits. These advanced systems can reduce energy consumption by up to 30%, allowing industries to not only lower operational costs but also contribute positively to environmental sustainability. As organizations strive for greener practices, the adoption of such innovative technologies aligns perfectly with the growing trend towards energy-efficient solutions in various sectors.

Tips for enhancing energy efficiency in your operations include regularly assessing existing systems for possible upgrades to magnetic linear drives. Additionally, consider integrating AI-driven analytics to optimize energy usage in real-time, thus maximizing the effectiveness of energy-saving technologies. Emphasizing the use of renewable resources and sustainable materials in your projects will further bolster your commitment to reducing carbon footprints.

Moreover, even minor adjustments can lead to substantial savings. Simple practices, such as switching to energy-efficient LED lighting or adopting smarter HVAC systems, can have a noteworthy impact. Engaging in energy efficiency programs and supporting initiatives that prioritize sustainability will not only benefit your organization but also play a vital role in the larger push towards a more energy-conscious future.

In the realm of automation, the comparison between magnetic linear drives and traditional solutions reveals significant advancements in efficiency and sustainability. Traditional automation systems often rely on mechanical components such as gears and belts, which can lead to increased friction and wear, resulting in higher energy consumption. In contrast, magnetic linear drives utilize electromagnetic technology for direct motion, effectively eliminating mechanical losses and enhancing overall performance. This innovative approach not only streamlines operations but also contributes to a reduction in maintenance costs and downtime.

Moreover, the energy savings associated with magnetic linear drives are substantial, with reports indicating potential savings of up to 30%. This efficiency stems from their ability to deliver precise positioning and rapid acceleration without the inertia typically present in conventional systems. By harnessing these capabilities, industries can optimize production processes, reduce their carbon footprint, and allocate resources more judiciously. As businesses increasingly seek eco-friendly solutions, the transition from traditional automation methods to magnetic linear drives represents a pivotal shift towards more sustainable operational practices.

| Parameter | Magnetic Linear Drives | Traditional Automation Solutions |

|---|---|---|

| Energy Efficiency | 30% Savings | Standard Efficiency |

| Maintenance Cost | Low | Moderate |

| Initial Investment | Higher | Lower |

| Speed | High | Moderate |

| Precision | High Precision | Standard Precision |

| Operating Environment | Flexible | Restricted |

| Noise Level | Low Noise | Higher Noise |

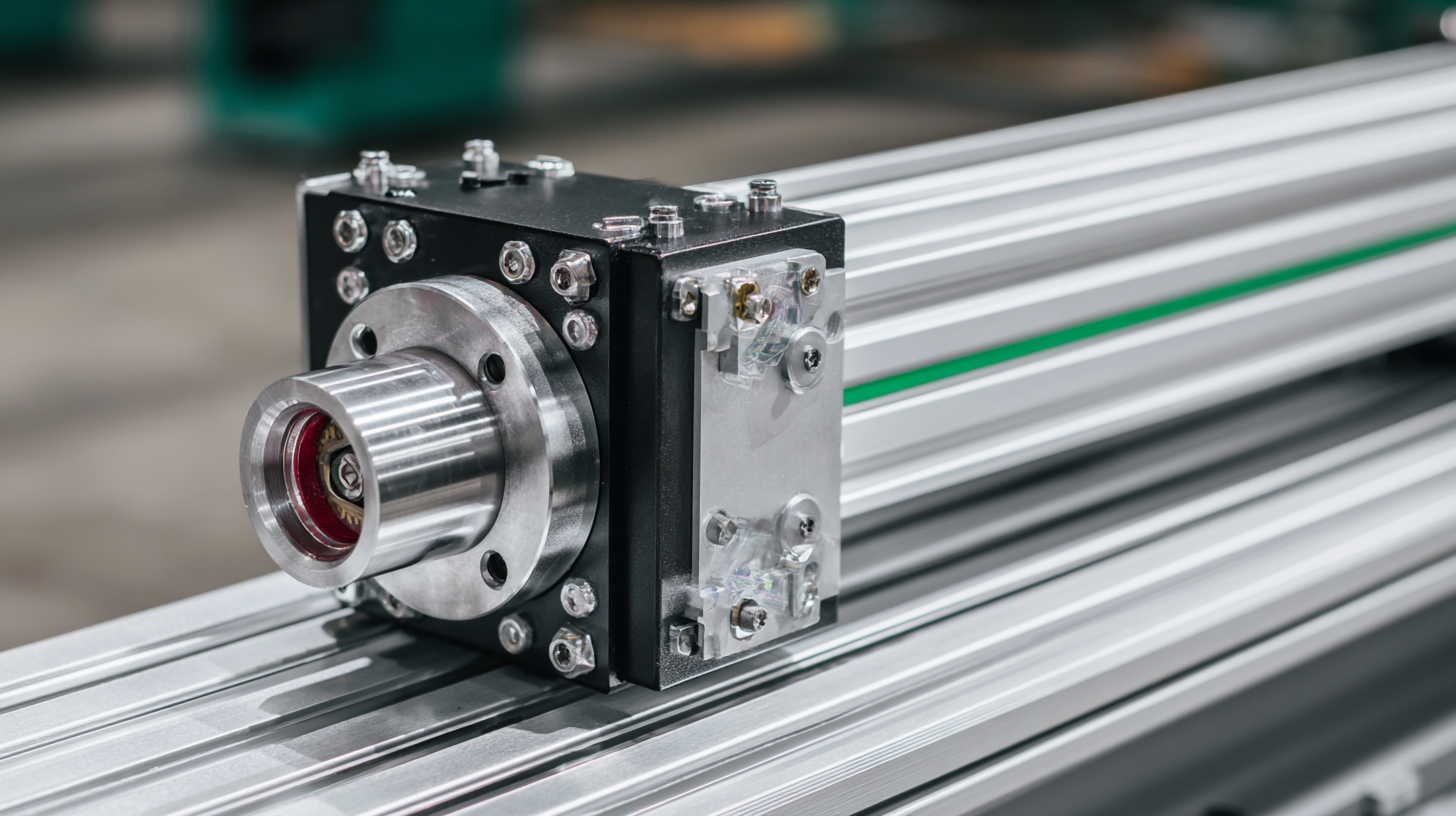

In the ever-evolving landscape of manufacturing and logistics, magnetic linear drives are emerging as a game-changer, bringing unprecedented efficiency and energy savings. These drives eliminate friction by using magnetic forces to propel objects along a track, resulting in smoother operation and reduced wear on components. This technology is particularly transformative in sectors that require high-speed, precise movements, such as automotive assembly lines and warehouse automation. By streamlining processes and enhancing performance, magnetic linear drives facilitate faster production cycles and improved overall productivity.

Moreover, the adaptability of magnetic linear drives makes them suitable for various industry-specific applications. In manufacturing, they enable flexible machinery configurations that can easily adjust to different product designs, reducing downtime during changeovers. In logistics, their precise positioning capabilities allow for optimized material handling, ensuring that goods are moved efficiently through complex supply chains. As industries continue to prioritize sustainability, the 30% energy savings offered by these drives not only contribute to lower operational costs but also support greener practices. With such compelling advantages, magnetic linear drives are poised to revolutionize automation across diverse sectors.

This chart illustrates the energy savings achieved by implementing magnetic linear drives across various industry applications, highlighting their significant role in enhancing automation efficiency.

The impact of magnetic linear drives on automation standards is profound, as these innovative systems are leading the charge in the evolution of motion control. According to recent industry reports, the adoption of magnetic linear drives can yield energy savings of up to 30%, significantly enhancing operational efficiency in automation processes. This efficiency is particularly critical in high-speed automation environments where speed and precision are paramount.

As industries pursue greater agility and responsiveness, magnetic linear drives offer a notable advantage. They not only reduce energy consumption but also improve system reliability and maintenance costs. For instance, a study by a leading automation research firm reveals that organizations integrating these drives have reported a 25% decrease in downtime. This capability to maintain high performance while consuming less energy is reshaping the benchmarks for automation standards, driving an overall shift toward more sustainable practices in manufacturing and logistics. With these trends in motion control, businesses are better positioned to meet the growing demands of an increasingly competitive market landscape.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.