Call Today: 916-259-1868

In the ever-evolving world of engineering and automation, the linear direct drive motor has emerged as a pivotal technology for numerous applications. Renowned expert Dr. Emily Harrison, a leading authority in motion control systems, emphasizes its significance, stating, “The precision and efficiency of a linear direct drive motor can redefine the standards of performance in various industries.” This innovative motor technology eliminates the complexities of mechanical linkages, offering unparalleled accuracy and responsiveness that designers and engineers increasingly seek for their next projects.

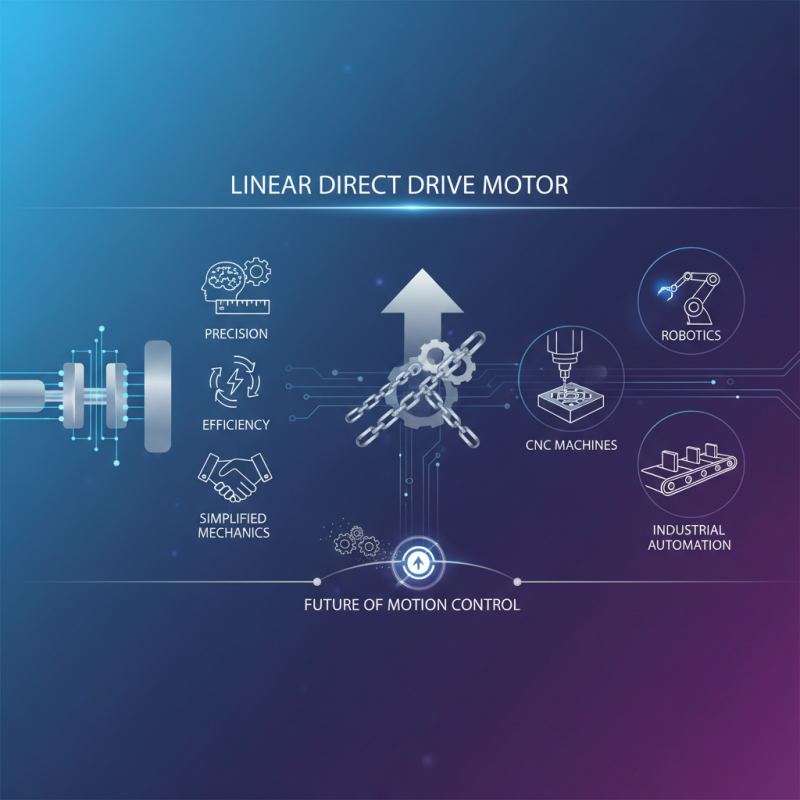

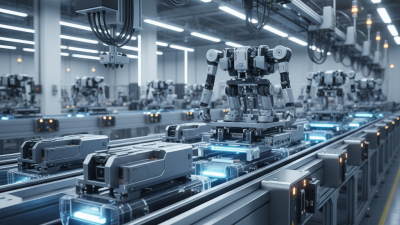

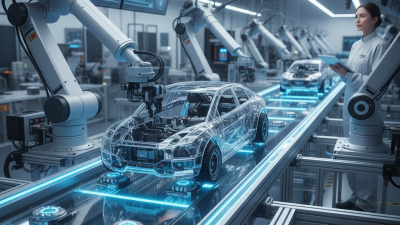

As more industries move towards automation and require higher levels of precision, the linear direct drive motor stands out as a solution equipped to meet these demands. By converting electrical energy directly into linear motion, these motors provide a straightforward and effective means of driving applications ranging from robotics to CNC machines. The growing interest in this technology reflects a broader trend towards sleek, efficient designs that facilitate performance enhancement while minimizing maintenance needs.

In conclusion, choosing a linear direct drive motor for your next project not only promotes operational efficiency but also opens up new possibilities for innovation and design. As organizations continue to prioritize speed and precision in their processes, the integration of this advanced motor technology is likely to become a standard practice, fostering new heights in automation and motion control.

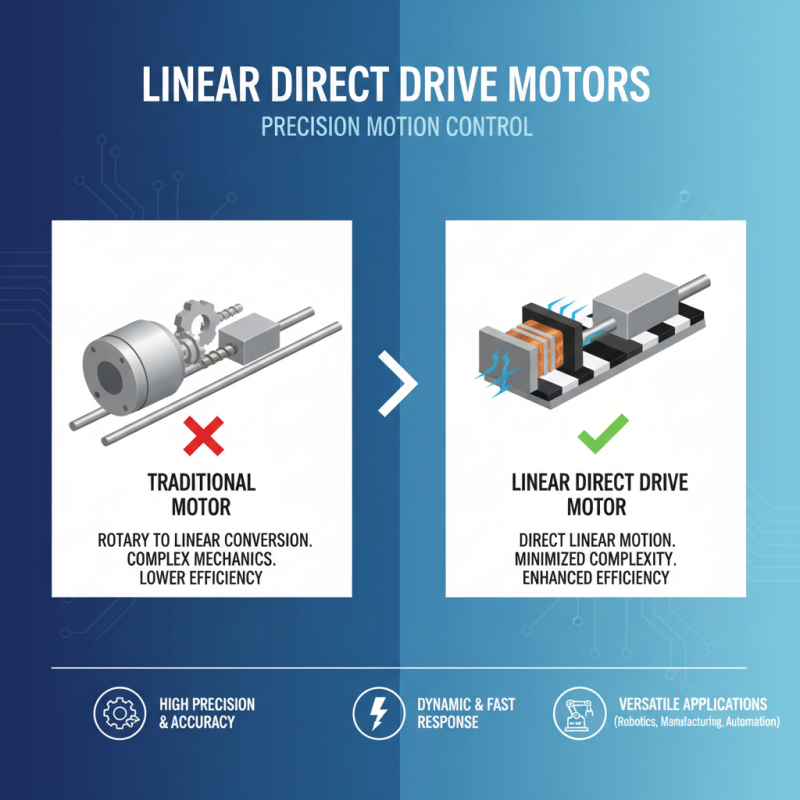

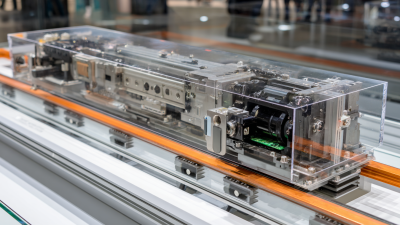

Linear direct drive motors are an innovative technology that offers precise motion control, making them ideal for various applications. Unlike traditional rotary motors that require a conversion mechanism to create linear movement, linear direct drive motors convert electrical energy directly into linear motion. This results in minimized mechanical complexity and enhanced efficiency. Their design typically includes a coil system that generates a magnetic field, which interacts with a magnetic track to produce powerful and accurate movements in a straight line.

One of the key advantages of linear direct drive motors is their ability to provide high-speed operation with minimal lag. The absence of gears and belts reduces friction and wear, leading to longer maintenance intervals and greater reliability over time. Additionally, these motors deliver smooth motion, which is vital in applications requiring delicate handling, such as in robotics or semiconductor manufacturing. The straightforward mechanics allow for easier integration into various systems, reducing the time and resources needed for installation and configuration. As industries seek more efficient and reliable solutions, understanding the basics and mechanics of linear direct drive motors becomes essential for making informed decisions in project development.

Linear direct drive motors (LDDMs) are increasingly gaining traction in various industries due to their numerous advantages over traditional systems. One of the primary benefits is their superior precision and responsiveness. According to a report by the International Society of Automation, systems utilizing linear direct drive technology can achieve position accuracy within 5 microns, significantly outperforming traditional servo systems that typically have accuracies of around 20 microns. This precision is crucial in applications where minute positional adjustments are essential, such as in semiconductor manufacturing or advanced robotics.

Another compelling advantage of LDDMs is their enhanced efficiency and reduced maintenance needs. Traditional drive systems often involve complex gear mechanisms that create friction and wear over time, leading to increased power consumption and downtime for maintenance. In contrast, LDDMs, which typically operate without gearboxes, can deliver greater energy efficiency — studies have shown that they can operate at efficiencies exceeding 90%. Furthermore, the absence of gears results in less mechanical wear, contributing to longer lifespans and lower operational costs. As industries push for more automated and efficient solutions, the shift towards linear direct drive motors highlights a significant evolution in technology that aligns with modern demands for reliability and performance.

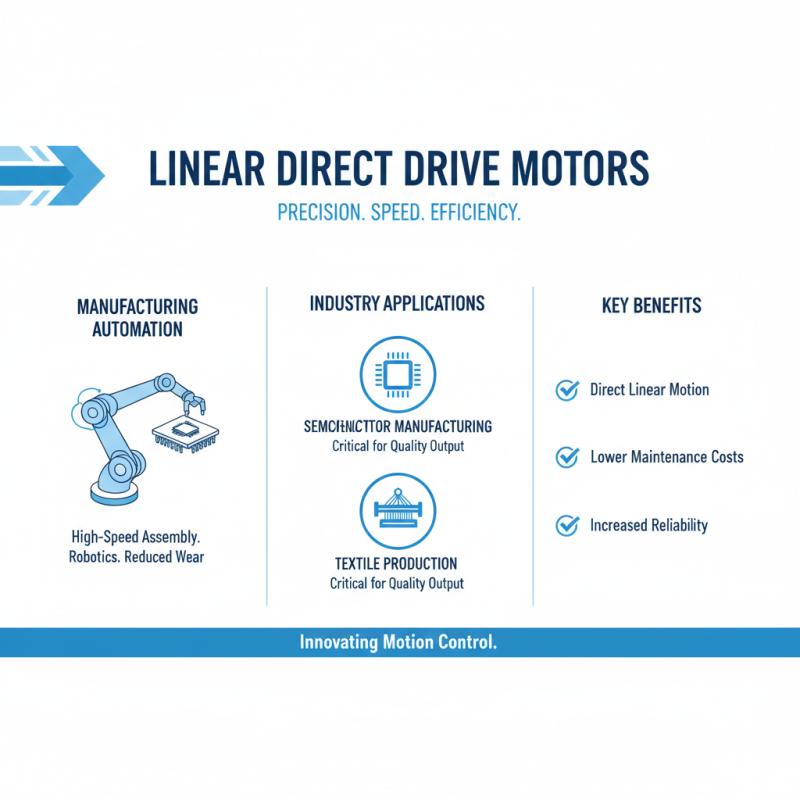

Linear direct drive motors are increasingly being integrated into various industries due to their precision, speed, and efficiency in motion control. In the manufacturing sector, these motors play a crucial role in automation processes, enabling high-speed assembly lines and robotics to operate with remarkable accuracy. Their ability to provide direct linear motion without the need for mechanical gearing reduces wear and tear, resulting in lower maintenance costs and increased reliability. This technology is particularly beneficial in applications like semiconductor manufacturing and textile production, where precision and speed are critical for quality output.

In the field of transportation, linear direct drive motors are enabling advancements in high-speed trains and magnetic levitation systems. By providing smooth and rapid acceleration, these motors enhance travel comfort and efficiency, allowing for shorter travel times and reduced energy consumption. Additionally, the medical industry benefits from this technology in applications such as MRI machines and robotic surgery systems, where precise positioning and movement are essential for patient safety and diagnostic accuracy. As industries continue to seek innovative solutions to enhance productivity and performance, linear direct drive motors are proving to be a transformative force in modern engineering.

When selecting a linear direct drive motor for your next project, several factors must be taken into account to ensure optimal performance and efficiency. First, consider the loading requirements of your application. The motor's force and speed must align with the demands of your specific use case. Understanding the weight and inertia of the load can help in choosing a motor that delivers the necessary thrust without compromising precision.

Additionally, evaluating the motion profile is crucial. Different applications require varying acceleration and deceleration rates, which can significantly affect the motor's performance. For instance, if your project demands quick starts and stops, a motor with low inertia may be preferable. Always assess the duty cycle as well—whether the motor will operate continuously or intermittently can influence the selection of cooling systems and the motor's lifespan.

**Tip:** When determining your application's voltage and current requirements, remember that higher voltages can allow for more efficient power usage, while lower currents can help reduce heat generation, therefore extending the motor's life and improving reliability.

Another essential consideration is the environmental factors. If the motor will operate in harsh conditions—such as extreme temperatures, dust, or humidity—it’s paramount to choose a model that can withstand these elements. Furthermore, compatibility with existing systems and ease of integration should also guide your choice.

**Tip:** Always check for standardized communication protocols between the motor and your control system to simplify the integration process and ensure smoother operations.

| Factor | Description | Importance Level | Typical Applications |

|---|---|---|---|

| Precision | Direct drive provides high accuracy and repeatability in positioning. | High | Medical Equipment, CNC Machines |

| Speed | Allows for fast movements without gear backlash. | Medium | Packaging Automation, Robotics |

| Torque | High torque at low speeds without additional torque requirements. | High | Industrial Automation, Semiconductor Manufacturing |

| Maintenance | Fewer moving parts leads to reduced maintenance requirements. | Medium | Textile Machines, Automated Guided Vehicles |

| Cost | Higher initial investment compared to indirect drive systems. | Varies | Automatic Inspection Systems, Laboratory Equipment |

As industries increasingly seek precision and efficiency in automation, linear direct drive motors are becoming a pivotal technology in future developments. Recent studies have shown that the market for linear direct drive systems is projected to grow at a compound annual growth rate (CAGR) of over 8% from 2023 to 2030, reaching an estimated value of $2.5 billion by 2030. This surge can be attributed to their ability to provide high-resolution positioning, reduced mechanical wear, and energy efficiency, making them ideal for applications in robotics, CNC machines, and automation systems.

Moreover, ongoing advancements in materials science and digital control technologies are poised to enhance the performance of linear direct drive motors significantly. For instance, the integration of advanced semiconductor technology has led to more responsive motor control and energy recuperation methods, increasing overall system efficiency by as much as 25%. Industry reports also emphasize that innovations in packaging and miniaturization will enable these motors to be employed in smaller devices, boosting their versatility across various sectors including aerospace, medical devices, and consumer electronics. These trends indicate a robust future for linear direct drive motor technology, aligning with the increasing demand for automation and precision in manufacturing processes.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.