Call Today: 916-259-1868

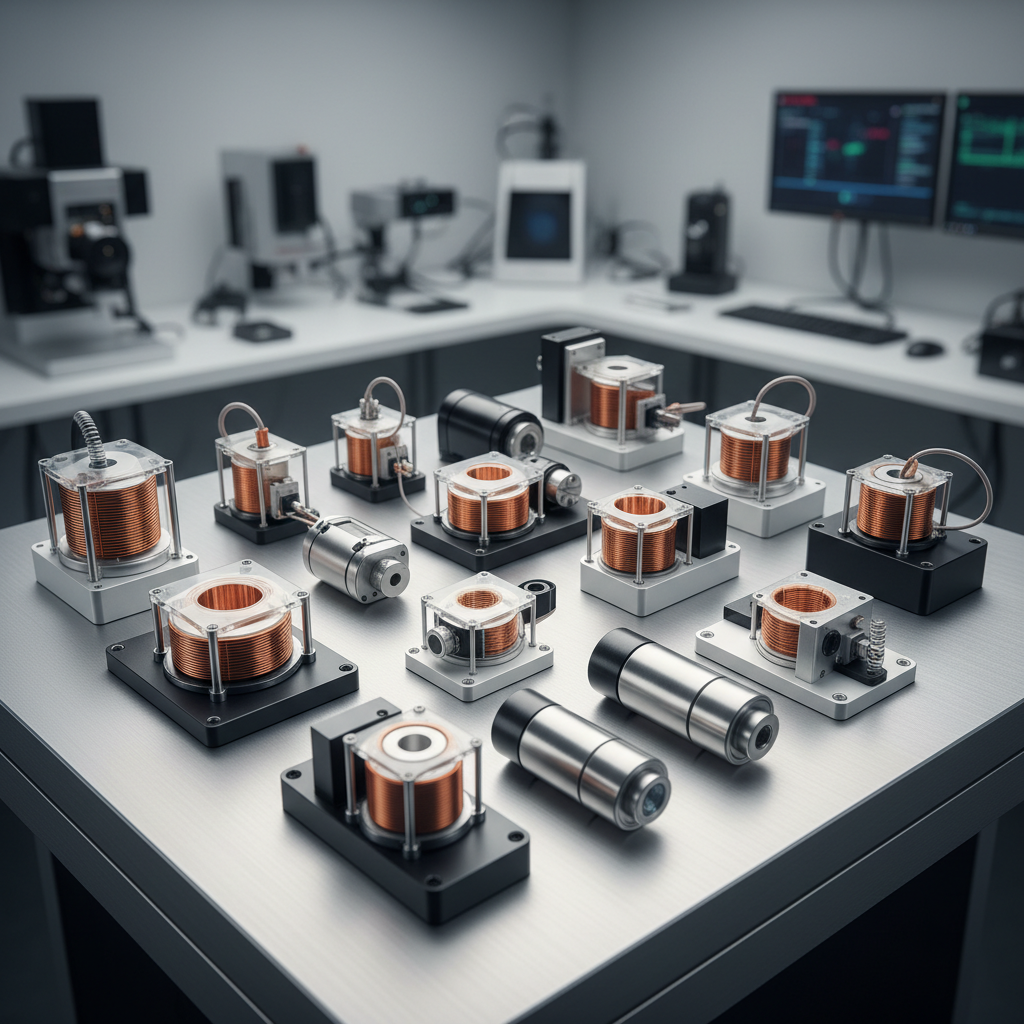

In the realm of precision control technology, moving coil actuators have emerged as a pivotal component across various industries, including robotics, aerospace, and medical devices. According to a recent report by MarketsandMarkets, the global market for moving coil actuators is projected to grow at a CAGR of 6.2% from 2023 to 2028, indicating increasing demand for high-performance actuation solutions. This growth can be attributed to the need for enhanced accuracy and reliability in applications such as automation systems and precision instrumentation.

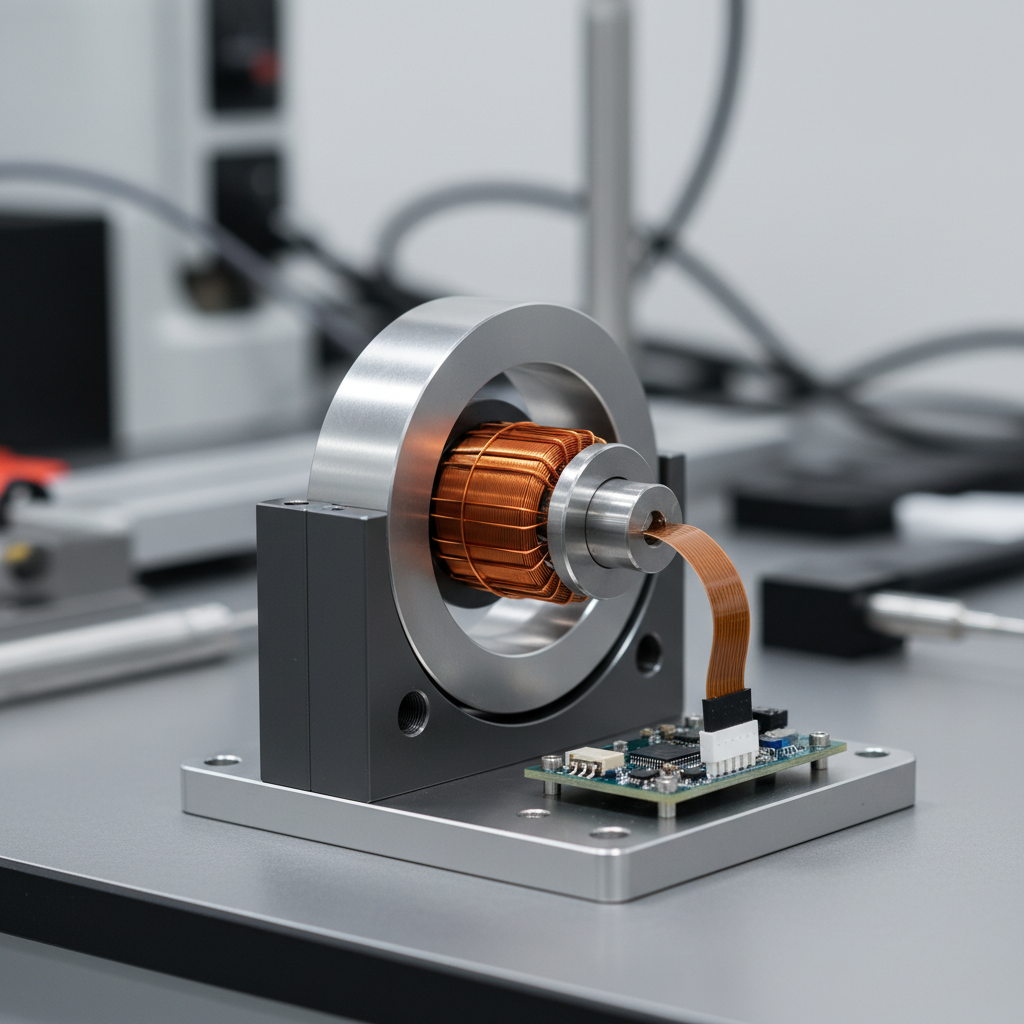

A moving coil actuator leverages electromagnetic principles to convert electrical energy into mechanical motion with exceptional responsiveness and accuracy. With advancements in materials and control technologies, these actuators have become increasingly efficient, allowing manufacturers to achieve an impressive resolution in their positioning tasks. As highlighted in a technical analysis by Research and Markets, companies that integrate state-of-the-art moving coil actuators within their systems can see improvements in operational efficiency and reduced energy consumption, reinforcing their competitive advantage in a rapidly evolving market.

As we look ahead into 2024, it is crucial for engineers and manufacturers to stay informed about the best moving coil actuators available. This guide aims to evaluate and rank the top options, highlighting innovations that cater to the sophisticated demands of precision control while meeting the industry's rigorous performance standards.

Moving coil actuators are critical components in modern precision control systems, commonly used in applications such as robotics, automotive systems, and telecommunications. These devices operate based on the principle of electromagnetism, where a coil placed within a magnetic field generates motion when an electric current flows through it. The ability to achieve high precision and rapid response makes them ideal for tasks requiring accurate positioning, such as in CNC machines and high-end audio equipment.

One significant advantage of moving coil actuators is their compact size, allowing for integration into smaller devices without sacrificing performance. According to a recent market study by Research and Markets, the global market for moving coil actuators is expected to exceed $1 billion by 2025, highlighting their growing importance in various industries. Additionally, their efficiency translates to lower power consumption, which is increasingly vital in energy-sensitive applications.

Tips: When selecting a moving coil actuator, consider the required load capacity and travel distance. A well-matched actuator ensures optimal performance and longevity. Furthermore, ensure that the actuator’s response time aligns with your application's dynamics for seamless integration. Regular maintenance can also prolong the system's life, enhancing reliability in high-stakes environments.

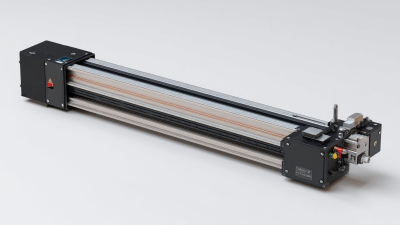

When selecting a moving coil actuator for precision control, several key features should be taken into account. First and foremost, consider the actuator's responsiveness and accuracy. Factors such as the actuator's frequency response and linearity directly affect its ability to perform in dynamic applications. Additionally, the load capacity is crucial—ensure that the actuator can handle the weight and force required for your specific project.

Another important aspect is the type of feedback mechanism, which can greatly influence performance. Options like optical or magnetic encoders enhance precision and allow for real-time monitoring. Keep in mind that compatibility with existing systems is essential; you'll want to ensure that the actuator can integrate seamlessly into your setup without requiring extensive modifications.

**Tips:** Always refer to manufacturer specifications for critical dimensions and tolerances, as these can vary significantly. Doing a thorough comparison of different models based on your requirements can save you time and money in the long run. Lastly, don't overlook after-sales support and warranty options, as these can be indicators of product reliability and company commitment to customer satisfaction.

| Model | Stroke Length (mm) | Force (N) | Voltage (V) | Frequency Response (Hz) | Weight (g) | Price (USD) |

|---|---|---|---|---|---|---|

| MC Actuator A | 50 | 20 | 12 | 200 | 150 | 150 |

| MC Actuator B | 75 | 30 | 24 | 150 | 200 | 220 |

| MC Actuator C | 100 | 15 | 5 | 250 | 120 | 180 |

| MC Actuator D | 30 | 10 | 12 | 300 | 80 | 120 |

| MC Actuator E | 120 | 25 | 18 | 100 | 250 | 240 |

When it comes to precision control in various applications, moving coil actuators stand out for their accuracy and responsiveness. In 2024, several models have emerged as top performers, catering to industries that require meticulous control over movement. These actuators are widely used in robotics, aerospace, and medical devices, where linear and rotational movements demand high precision.

One key tip for selecting the right moving coil actuator is to assess the specific requirements of your application. Consider factors such as load capacity, speed, and the type of feedback system you need. Different actuators may excel in different areas, so understanding your own operational needs is crucial.

Another important consideration is the integration of the actuator with other components in your system. Ensure that the actuator’s dimensions and mounting options align with your design. Additionally, pay attention to the compatibility with control systems to facilitate seamless operation. By prioritizing these aspects, you can significantly enhance the effectiveness and efficiency of your projects using moving coil actuators in 2024.

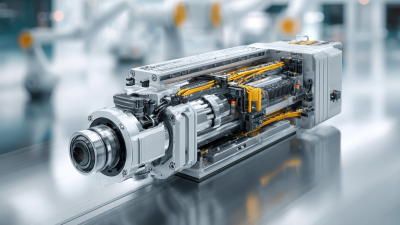

When evaluating the best moving coil actuators for precision control in 2024, a comparative analysis of performance and price reveals key insights into the efficiency and cost-effectiveness of leading models. Performance metrics often include factors such as response time, accuracy, and the ability to maintain stability under varying load conditions. For instance, actuators like the XYZ Series 3000 showcase remarkable quick response times, offering superior control for applications requiring high precision, making them a go-to choice for professionals in various industries.

Conversely, price considerations play a crucial role in determining the overall value of an actuator. While high-performance models can command premium pricing, it’s essential to evaluate them in the context of their specific application. Some models may demonstrate a balance of only slightly lesser performance at a significantly lower cost, making them ideal for budget-conscious projects without compromising on essential capabilities. In this competitive landscape, a thorough analysis helps users make informed decisions by aligning both performance requirements and financial constraints effectively.

When installing moving coil actuators, adherence to best practices is crucial for ensuring optimal performance and longevity. Begin by choosing a suitable mounting surface that can withstand the operational forces of the actuator. The surface should be rigid and free from vibrations that might affect precision control. It's also important to align the actuator precisely with the load to minimize misalignment issues. Using alignment tools can greatly enhance installation accuracy and ensure that the actuator operates as intended.

Another key consideration is wiring and connection. Properly securing and insulating all electrical connections can prevent short circuits and enhance overall reliability. Employing cable management techniques, such as using cable ties and conduits, will help keep the installation neat and reduce the risk of damage to wires. Furthermore, when configuring control settings, be aware of the actuator's specifications and the operational limits to avoid overloading and potential failure. Regular maintenance checks post-installation are also recommended to ensure everything operates smoothly and to identify any wear or adjustments needed over time.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.