Call Today: 916-259-1868

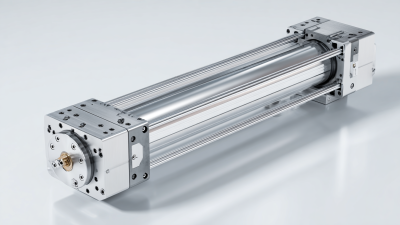

In modern industrial applications, efficiency and precision are paramount. Brushless linear motors have emerged as a game-changing technology. These motors offer significant advantages over traditional systems. According to a report by the International Journal of Advanced Manufacturing Technology, brushless linear motors can enhance speed by up to 30% compared to conventional motors.

The elimination of mechanical commutation in brushless linear motors reduces wear and maintenance needs. This leads to a longer operational lifespan. Industry data shows that an effective brushless linear motor can last up to 15,000 hours in continuous operation. However, the initial equipment costs can be higher. Companies must weigh these upfront investments against long-term savings.

While the benefits are substantial, some challenges remain. The complexity in integration with existing systems can deter some industries. Companies often face difficulties during the transition phase. Yet, as the demand for automation increases, the shift towards brushless technology appears inevitable. Understanding these dynamics can help industries harness the full potential of brushless linear motors.

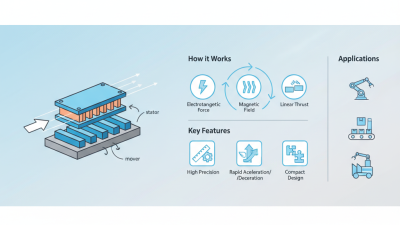

Brushless linear motors are revolutionizing modern applications. They provide seamless motion without relying on traditional gears. Understanding their principles can enhance efficiency in various fields. These motors use electromagnetic forces for linear motion, eliminating friction found in conventional motors. This results in lower maintenance and increased longevity.

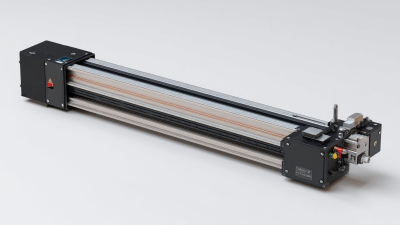

Placement matters. Ensure the motor aligns perfectly with its application. Misalignment can cause inefficiencies. In addition, consider environmental factors. Vibrations or temperature changes can affect performance. Regular assessments are essential for optimal operation.

Tip: Always prioritize quality materials. They can significantly influence motor durability. Also, remember that the initial cost may be higher. But, the long-term savings will benefit operations in the end. A careful analysis of needs and expected outcomes will guide the right decisions.

Brushless linear motors are revolutionizing industrial automation. They offer high efficiency and precise control. These motors operate without brushes, reducing mechanical wear and maintenance needs. This means less downtime for repairs and increased productivity.

Speed is a significant factor. Brushless linear motors can achieve rapid acceleration and deceleration. For applications requiring quick movements, they excel. However, implementing them in older equipment can be challenging. Retrofits may face compatibility issues with existing systems. This complexity can deter some manufacturers from upgrading.

Energy efficiency is another advantage. Brushless linear motors consume less power, leading to reduced operational costs. They generate less heat, which improves reliability. Yet, the initial investment can be substantial, making financial planning critical. Balancing these benefits against costs is a vital consideration for businesses looking to automate their processes.

| Advantage | Description | Impact on Automation |

|---|---|---|

| High Efficiency | Reduced energy consumption and heat generation. | Lower operating costs and improved performance. |

| Low Maintenance | No brushes to wear out, leading to longer life cycles. | Reduced downtime and maintenance costs. |

| Compact Design | Space-saving form factors for limited installations. | Increased flexibility in layout and design. |

| Improved Precision | High accuracy in positioning and motion control. | Enhanced product quality and process reliability. |

| High Speed | Rapid response and acceleration capabilities. | Increased productivity and throughput. |

| Quiet Operation | Minimal noise levels during operation. | Improved working environment for operators. |

| High Acceleration | Ability to start and stop quickly, enhancing cycle time. | Faster operational sequences and reduces time wasted in motion. |

| Environmentally Friendly | No oil or grease required, reducing environmental impact. | Complies with modern environmental regulations and standards. |

| Customization Options | Flexible configurations for diverse applications. | More tailored solutions for specific industrial needs. |

| High Torque | Suitable for heavy load applications without gearboxes. | Improves reliability and reduces complexity in systems. |

Brushless linear motors offer substantial benefits in transportation. One key advantage is increased efficiency. According to a recent industry report, these motors can achieve over 90% efficiency. This means less energy wasted and lower operational costs. The ability to convert electrical energy directly into linear motion minimizes energy loss. It leads to faster response times and improves overall system performance.

Reliability is another strong point. Brushless linear motors have fewer moving parts, reducing wear and tear. This results in longer life cycles than traditional motors. A study showed that equipment using brushless motors saw a 30% reduction in maintenance requirements. Fewer maintenance needs mean higher uptime, benefiting critical transportation systems. There's a tangible improvement in reliability metrics, but potential flaws still exist in implementation. Maintenance checks remain essential to ensure peak performance.

While the advantages are clear, challenges persist. Initial costs can deter some operations. Additionally, integrating these motors into existing systems may require significant adjustments. According to experts, proper assessment and planning are crucial for successful integration. It's essential to weigh the long-term savings against upfront investments.

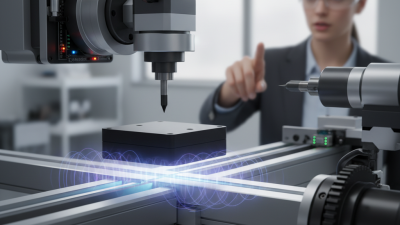

Brushless linear motors are revolutionizing robotics and precision engineering. These motors deliver high precision and efficiency, essential for modern applications. Reports show that their efficiency can exceed 90%, significantly outperforming traditional systems. In robotics, they enable quick movements and seamless integration, crucial for tasks like assembly and material handling.

In precision engineering, brushless linear motors are gaining traction for their reliability and reduced maintenance needs. They generate less heat and noise, which creates a better working environment. Some studies indicate that companies using these motors have reported up to a 40% increase in productivity. However, the initial setup can be complex, requiring skilled personnel for optimal integration.

Despite their advantages, challenges remain. The high cost of these motors can be a barrier for small businesses. Not every application may benefit from brushless technology. Careful evaluation is needed for each project. Users should reflect on their specific needs to determine if the investment is justifiable. This consideration is crucial to reaping the full benefits of brushless linear motors in industrial settings.

Brushless linear motors are gaining traction in diverse applications. Their efficiency, precision, and low maintenance are notable advantages. The future points towards further innovations in this field. For instance, as industries seek automation, the demand for these motors is set to rise significantly.

Emerging trends include enhanced control algorithms. These advancements improve response times and operational stability. Combine this with smart sensors, and you get real-time performance feedback. This integration helps optimize energy consumption. However, some engineers are still grappling with designing fully compatible systems. The learning curve is steep, and not all solutions are effective right away.

Another trend involves miniaturization. As more devices require compact solutions, manufacturers are obliged to rethink motor designs. Smaller motors can lead to more challenges in heat dissipation and efficiency. This requires innovation and creativity. There’s still uncertainty in achieving reliable performance at reduced sizes. Balancing compactness with functionality presents ongoing engineering dilemmas.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.