Call Today: 916-259-1868

In the rapidly evolving landscape of automation and robotics, the significance of a linear motor controller cannot be overstated. As industries seek increased efficiency and precision in their operations, these controllers have become indispensable components in various applications ranging from manufacturing to transportation. Dr. Emily Carter, a leading expert in motion control technologies, states, "The future of automation hinges on our ability to harness the precision and power of linear motor controllers, enabling engineers to push the limits of innovation."

This comprehensive guide delves into the top features and benefits of linear motor controllers projected for 2025, offering insights into their applications across diverse sectors. With advancements in technology, these controllers are not merely components but pivotal enablers of high-performance systems. Their design principles allow for remarkable speed, acceleration, and positioning accuracy, setting new benchmarks for performance in linear motion tasks.

As we explore the key characteristics that define the next generation of linear motor controllers, it becomes evident that understanding both their functionality and application relevance is crucial for industries aiming to thrive in an increasingly competitive market. From robotics to material handling, linear motor controllers are poised to revolutionize the way we approach automation, making it essential for engineers and decision-makers to stay informed about these advancements.

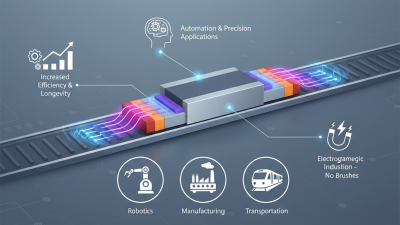

Linear motor controllers play a crucial role in the automation and precision of motion control systems. These controllers facilitate real-time management of linear motors, enabling precise positioning and speed control essential for various applications, including robotics, CNC machining, and automated material handling. According to a report by MarketsandMarkets, the linear motor market is projected to reach USD 9.06 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020. This growth is driven by the increasing demand for automation and the need for improved efficiency in industrial operations.

The functionality of linear motor controllers extends beyond basic control capabilities. These devices are designed to enhance system performance through features like high responsiveness, reduced thermal effects, and the ability to handle dynamic loads effectively. The integration of advanced algorithms for feedback and motion planning leads to smoother operation and increased system reliability. Industry experts highlight that the adoption of linear motor technology contributes to a significant reduction in operational costs and downtime, underscoring the importance of selecting the right controller for optimizing system performance. As applications become more complex, the demand for sophisticated linear motor controllers with enhanced computational capabilities is likely to rise, making understanding their features and benefits more essential for manufacturers and engineers alike.

| Feature | Benefits | Applications |

|---|---|---|

| High Precision | Increased accuracy and repeatability of movements | Material handling, CNC machining |

| Compact Design | Saves space in machine layouts | Robotics, automation systems |

| High Speed | Reduces cycle times and increases productivity | Pick and place operations, conveyor systems |

| Low Maintenance | Lower overall operating costs and downtime | Assembly lines, packaging machinery |

| Dynamic Response | Enhanced control over acceleration and deceleration | Medical devices, semiconductor manufacturing |

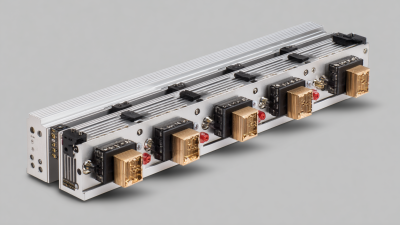

As the demand for precision and efficiency in automation and robotics increases, the linear motor controller market is evolving to meet these needs. The key features of top linear motor controllers in 2025 are designed to enhance performance and usability. High-speed control algorithms ensure rapid response times, facilitating smoother and more precise movements. Additionally, advanced feedback systems, such as high-resolution encoders, allow for better accuracy in positioning, which is critical in applications requiring meticulous detail, such as semiconductor manufacturing and analytical instruments.

When selecting a linear motor controller, consider the compatibility with your existing systems. Ensure that the controller can integrate seamlessly and supports the required communication protocols. Moreover, assess the scalability of the controller; as projects evolve, having a controller that can adapt to increasing demands will save time and resources in the long run.

Another essential feature is the energy efficiency of the controller. Modern linear motor controllers are designed to minimize power consumption while maximizing performance. This not only reduces operational costs but also contributes to more sustainable practices in industrial applications. Make sure to evaluate the cooling requirements and thermodynamic management of the controller, which can significantly impact its longevity and reliability.

Linear motor controllers have become increasingly popular in various applications, thanks to their significant advantages over traditional motor control methods. One of the primary benefits is their ability to deliver precise and highly responsive motion control. According to a recent industry report, the linear motion market is projected to grow at a CAGR of 8% from 2023 to 2028, driven by the rising demand for automation in manufacturing processes and robotics. This growth underscores the importance of incorporating advanced linear motor controllers for achieving operational efficiency and accuracy.

In addition to providing enhanced precision, linear motor controllers also bring substantial energy savings. Utilizing direct drive technology, these controllers minimize energy losses associated with mechanical components such as gears and belts. Studies suggest that industries can reduce energy consumption by up to 30% when switching from conventional to linear motor systems. Furthermore, the simplicity in design often translates to lower maintenance costs and improved system reliability, making them ideal for applications ranging from material handling to robotic automation.

Tips: When selecting a linear motor controller, consider the specific application requirements, including load capacity and speed. It's essential to evaluate the controller’s compatibility with existing systems to maximize performance. Additionally, implementing a robust maintenance schedule can further enhance the longevity and efficiency of the motor controller, ensuring optimal performance throughout its lifecycle. Choosing the right features can significantly contribute to achieving the desired operational outcomes while minimizing downtime.

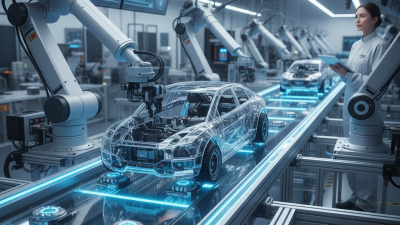

Linear motor controllers are becoming increasingly integral across various industries due to their precision and efficiency. In manufacturing, these controllers enable rapid and accurate movement in automated machinery, enhancing production rates while reducing downtime. Their ability to deliver high levels of torque and speed while maintaining precise positioning makes them ideal for applications such as CNC machining and industrial robotics. This not only streamlines operations but also allows for more complex and intricate production processes.

In the transportation sector, linear motor controllers are being utilized in high-speed trains and magnetic levitation systems. The seamless integration of these controllers promotes smoother acceleration and deceleration, improving ride comfort and energy efficiency. Furthermore, the less mechanical wear and tear associated with linear motors contributes to reduced maintenance costs, making them a preferred choice for modern transit solutions. Additionally, the medical industry has begun to adopt linear motor technology in equipment like MRI machines and automated laboratory systems, where precise movements translate to better imaging and analysis results. The versatility of linear motor controllers is thus transforming various sectors, driving innovation and efficiency.

The landscape of linear motor controller technology is rapidly evolving, driven by the need for higher performance and efficiency in various applications. Future innovations are set to focus on integrating advanced materials and smarter algorithms to enhance responsiveness and precision in linear motion systems. As manufacturers continue to prioritize sustainability, the development of energy-efficient controllers that minimize power consumption while maximizing output will become increasingly important. Intelligent control systems, equipped with machine learning capabilities, will also play a crucial role in optimizing performance, allowing for real-time adjustments based on operational conditions.

Another significant trend is the rise of connectivity and automation within linear motor systems. As industries move towards Industry 4.0, seamless integration of Linear Motor Controllers into IoT frameworks will provide enhanced monitoring and control capabilities. These advancements will allow for predictive maintenance, reducing downtime and prolonging equipment lifespan.

Moreover, the push towards modular designs will enable easier customization and scalability of linear motor systems, making them adaptable to diverse industrial applications ranging from robotics to precision manufacturing. The ongoing innovations in this field not only promise to elevate operational standards but also pave the way for entirely new applications that leverage the unique advantages of linear motor technology.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.